SAP PLM (Product Life-cycle Management)

Definition or Meaning - What is SAP PLM?

Full form or SAP PLM stands for (Product Lifecycle Management), the dynamics of business world keep changing every day on a global level and the same should reflect on the products that a company sells. One has to keep innovating and creating their products in such a manner that they differentiate themselves from their competitors. Thus, proper managing of a product lifecycle becomes crucial. New ideas for existing products or conceptualizing new products, ideating over manufacturing processes to have a better product and developing the product lifecycle as and when required, are some of the steps that should be considered to keep up with the changing business norms.

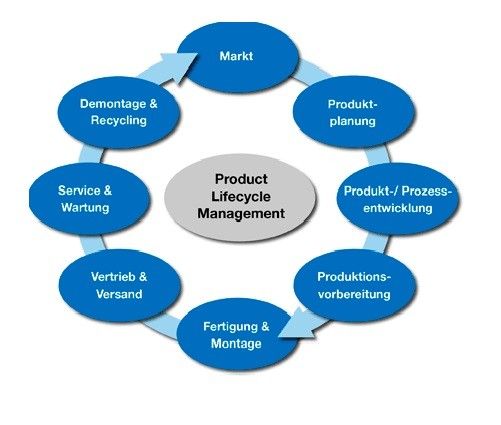

The SAP Product Lifecycle Management (PLM) or better known as PLM lends a hand in doing the same. It supports the business processes, right from the conceptualization of the idea right to the delivery of the product.

More about SAP Product Lifecycle Management (PLM)

The SAP Product Lifecycle Management (PLM) provides a 360 degree approach in managing all things related to the development and delivery of any product. All the tasks and activities involved with the manufacturing processes can be managed through this system. A layer of transparency is also achieved, thus smoothening out many aspects of different processes. Through this, you can also comply with all the industry regulations and document the production procedure and its performance.

Additionally, you can achieve the following with PLM:

- Create and design innovative methods and products to match the market’s demands. This will keep you at par with your competitors and you can have a strong market share.

- Make changes or modify your business processes involved with product development. This includes quality checks as well as compliance with regulatory standards and industry regulations.

- Enable you to respond promptly to any business changes and recognize the opportunities quickly.

- You can have a great interface with the SAP Supplier Relationship Management (SRM) software and procurement management system. It ably supports strategic sourcing and accelerates the product development cycle; thereby proving to be largely helpful before and during the manufacturing process.

- PLM provides insights to ongoing projects and gives access to data that would be helpful in making crucial decisions. You can also take advantage of flexible reporting as well as different analytics dealing with aspects such as product quality, product safety, portfolio management and occupational health.

- You can monitor the products through different development stages and keep a check on the factors affecting the same, such as timelines, resources, effort and money.

This helps in increasing the operative and strategic controls with regards to processing product development. - PLM offers relevant data, tools and services to all internal and external users, at all times. The data is quite role specific and can be accessed on the basis of the context.

- It focuses on delivering high quality products every single time; as well as keeping the wastage low at every phase of product development.

- PLM optimizes productivity through its role-based portal. It enables content delivery and enhances productivity greatly.

- It also provides an open-technology framework which is very helpful. It delivers real time data that would be necessary for different processes like procurement, sales, manufacturing etc.

What Next

The final product, as delivered by the company, is what matters to the consumers, so all companies should focus on presenting exactly that. It greatly helps an organization which reflects itself through high quality products and high customer services alike.

Tutorials

- Migration Steps from Recipe Management (RM) to Recipe Development (RD)

How to transfer the data in the existing recipes and independent formulas to Recipe Development (RD)? An option to migrate data is provided to enable the data from Recipe Management (PLM-RM) in Recip ... - Result Category in SAP

In this SAP PLM (Product Lifecycle Management) tutorial, we will learn how to define Result Catagories in the SAP system with the proper screenshots. What Result Category in SAP? The R ...